Aerospace machining

Our aerospace expertise

ROCH Mécanique de précision has been producing high-quality materials, ISO 9001 certified since 1996 and EN 9100 certified since 2003. Fifty percent of our turnover comes from key accounts in the aerospace machining industry. Discover more about our expertise and products for the aerospace market.

Machining for the aerospace industry

We have a highly trained, skilled and qualified team of employees. Our competitive machinery and clear organisational structure are the foundations of our expertise in precision machining for aerospace. With regards to quality, we are strict and thorough. This is an essential requirement when producing components for the aerospace industry. We have a history of aerospace machining experience, and we continue to expand our capabilities in this area. We are equipped with CNC lathes operating on up to 8 axes with bar passage up to Ø80 mm (3″) in diameter. Our high-precision CNC machines (Nakamura and Okuma), installed in an air-conditioned workshop, allow us to master the manufacture of high-precision parts for annual volumes ranging from 100 to 10000 components.

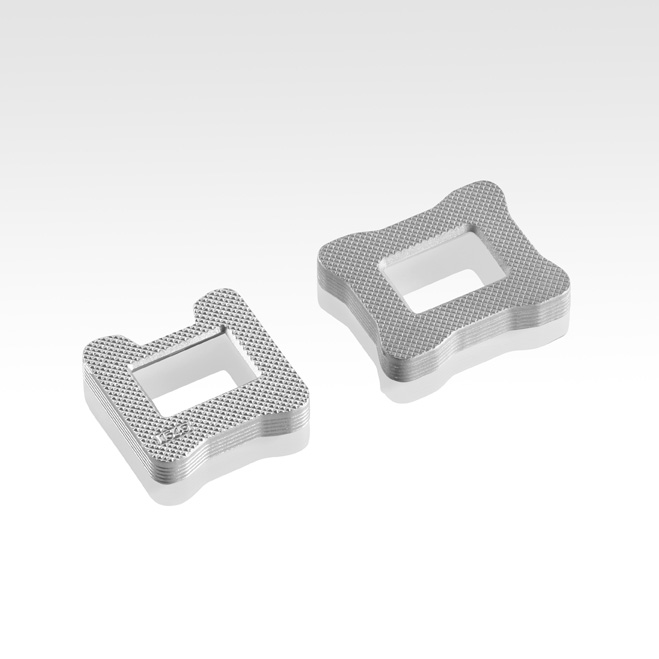

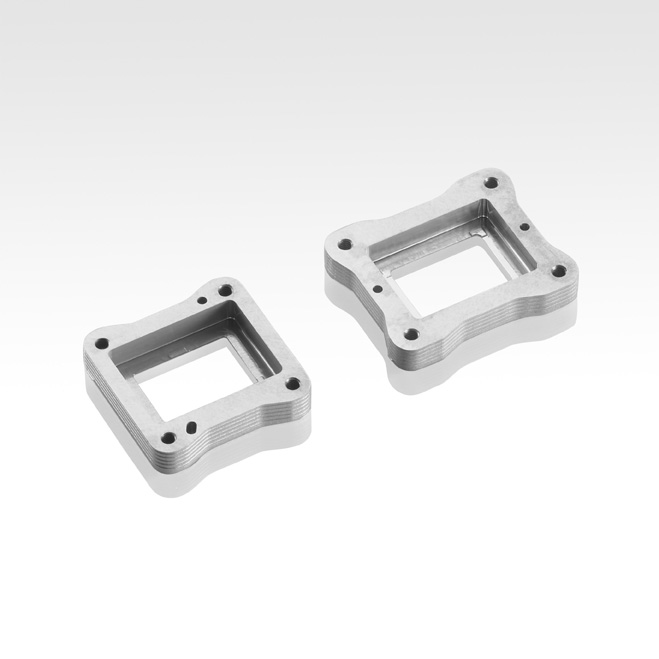

Electronics for the aerospace industry

ROCH Mécanique de précision has the technical ability to produce numerous mass-produced parts for aeronautical electronics in a wide range of materials including aluminium, stainless steel, titanium, plastic and Inconel.

Our production is focused on different types of cylindrical and rectangular connectors as well as contactor parts that are adapted to our machines. Our components are mainly used in the electronic core of airliners, i.e. the A320, A350 and various aircraft of the Boeing range.

Assembly of subassemblies for components for the aerospace industry

We can take care of various assemblies in order to deliver you a ready-to-use part. These include the assembly of pins, thread inserts, screws, several components and parts for kits.

We can assemble all types of inserts, including screw-locking, free-running and tang-free inserts. We have various manual and automatic tools at our disposal to maintain the optimum level of productivity according to the number of parts that need assembling.

Surface and heat treatments for aerospace machining

We have full expertise in the various heat treatments and surface treatments used in machining for the aerospace industry, including:

Heat treatments:

- Ionic and gas nitriding, Sursulf, oxy-nitrocarburising, etc.

- Case-hardening

- Tempering and stabilisation

- Custom heat treatments

Surface treatments :

- Anodizing sulphuric, chromic and hard oxidation, etc, with or without Alodine 1200, 1500, SurTec 650 protection, etc.

- Chemical conversion, Alodine 1200, Surtec 650

- Cadmium coating

- Galvanising

- Chemical nickel plating

- Black chromium plating

- Custom surface treatments

Roch Mécanique de précision is certified by the aerospace industry

ROCH Mécanique de précision has been producing high-quality parts, ISO 9001 certified since 1996 and EN 9100 certified since 2003. Click here to learn more about our certifications.