Milling

Roch Mécanique de précision: our milling process

Advantages of milling

The advantages of milling are: high efficiency, good surface finish and high precision, as well as the flexibility to produce different shapes. We are also able to machine areas that are usually inaccessible, by using special tools that allow us to remove material from a machined cavity.

Types of milling and their applications

Milling is most often used to produce flat surfaces, shoulders and grooves, but its efficiency in contouring is increasing, thanks to the use of CNC techniques.

This technology is particularly suited to manufacturing housing designed to accommodate:

- moving mechanical components: gearboxes

- rectangular connector bodies (connectors for all fields of activity, e.g. Harwin, Arinc, Harting etc)

- contactors and connecting parts (flanges, supports, mounting flanges, PCBs, electrical enclosures to protect sensitive equipment, camera supports etc)

- control devices (inertial measurement units, LVDT sensors, mass spectrometry cores, waterproof enclosures, etc).

The majority of materials machined are aluminium alloys

- AW 2017,

- AW 2024,

- AW 2618,

- AW 6060,

- AW 6061,

- AW 6082,

- AW 7175

But also all types of stainless steel (AISI 304, AISI 316, AISI 321, AISI 421, AISI 430, AISI 1-4028, AISI 1-4418), copper as well as magnesium alloys and superalloys (titanium, Inconel, Supra50, Invar etc).

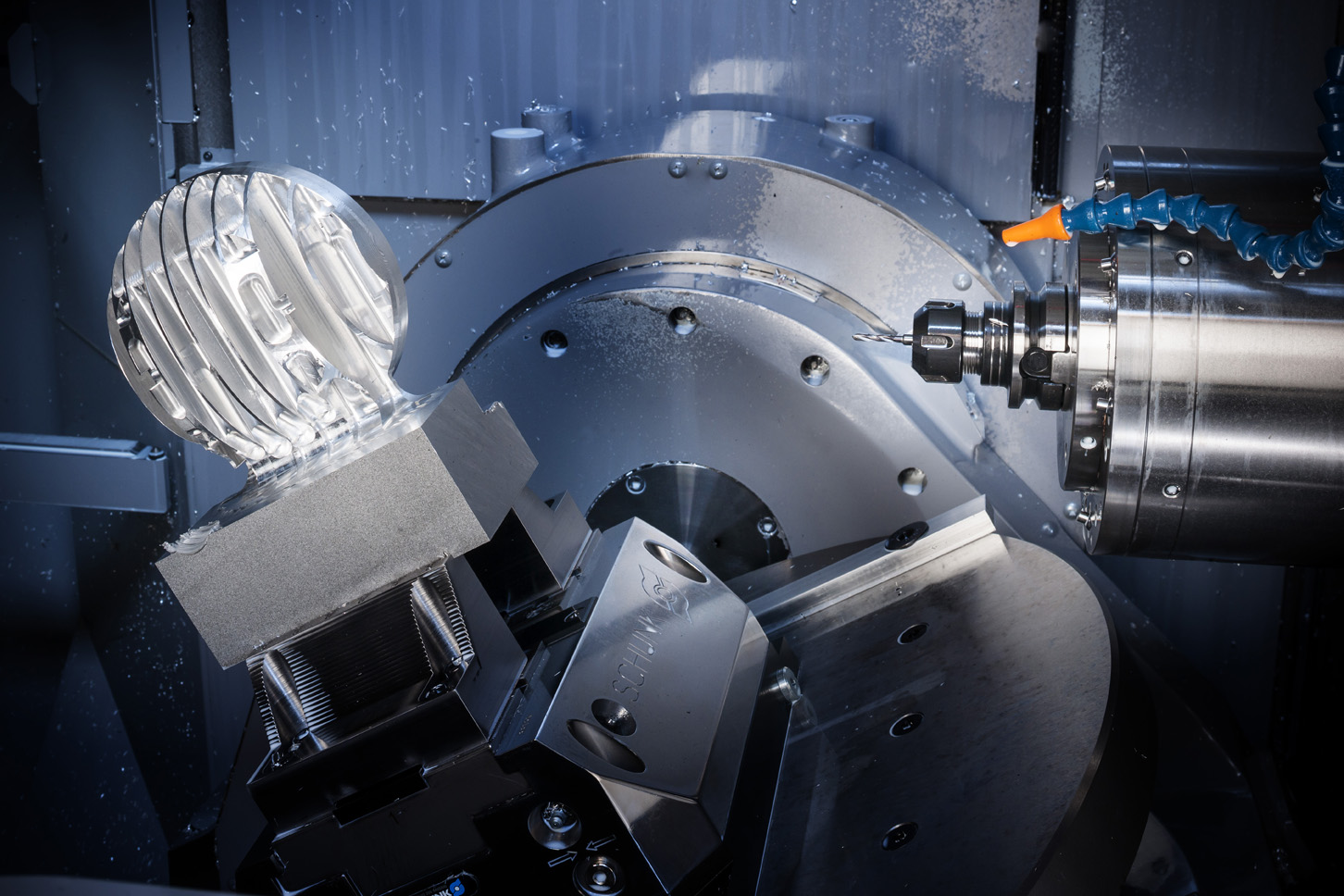

Special features of 5-axis and high-speed machining technology

Using spindles with high rotational frequencies, of up to 24,000 rpm, increases the speed of execution (high-speed machining) and also enables us to use machining strategies that limit the deformation of the material on the final product. Using 5-axis machining centres enables us to machine several faces of a part in the same operation and therefore provides better control of manufacturing tolerances. The simultaneous movement of the 5 axes on the machine means we can produce complex shapes. These machining technologies are widely used for the manufacture of mechanical components for the aerospace and medical sectors.

Product Quality Assurance (PQA) for milled parts

The milled parts are checked using CNC coordinate measuring machines. All accessible features (dimensions) are checked on these machines, including connection radii and chamfers. Almost all deburring is carried out on CNC machines. Our machine inventory consists of high-quality and reliable machines (OKK, Fanuc, DMG-Mori). Our engineers have also developed methods that allow us to control and monitor the machining processes throughout production directly on the machine.

Our milling machines

Our CNC milling centres, controlled by our qualified machine operators, are equipped with various options: 3, 4 and 5-axis milling, high-speed milling, a loading robot, high-pressure water jet, tool breakage control and a smoke extractor. Our optimised and controlled processes, meticulous preparation methods and automated machines give us a competitive positioning in milling machining. Our highly automated machining centres are able to operate 24/7.